ICB is Part of Fast Track to Innovation Project – SnapToPowerQuality

ICB is proud to announce that we are taking part in the Fast Track to Innovation Project “SnapToPowerQuality”. The project is funded by the European Union’s Horizon 2020 research and innovation program under grant agreement No 958600.

We are very happy to be part of the international team that is aiming to achieve an easy to use and very cost-effective solution to help cope with the power quality disturbance in industrial cases.

SnapToPowerQuality is a patented innovative AI (Artificial Intelligence) technology that is expected to revolutionize the control of power quality issues in production.

The challenge

Power quality issues are one of the main reasons for production break-down, production loss and energy loss. Tracking what caused the power issues would cut financial losses and save energy resources. Just in the European Union, the savings would amount at 151.7 billion Euro.

The existing market solutions are expensive and difficult to install as they must break into the multiconductor electricity cables to monitor the power quality.

The SnapToPowerQuality solution

SnapToPowerQuality is an unprecedented key-enabler technology as it resolved problems that have challenged IT innovators over a decade.

We combine clamp-on power sensors with cloud AI, to measure critical deviations in the power flow from the outside of existing multiconductor cables, instead of breaking into power installations. We use mathematical models to translate the data collected by the clamp-on sensors into an analysis of the impact on the power quality for all the machines in the production facility.

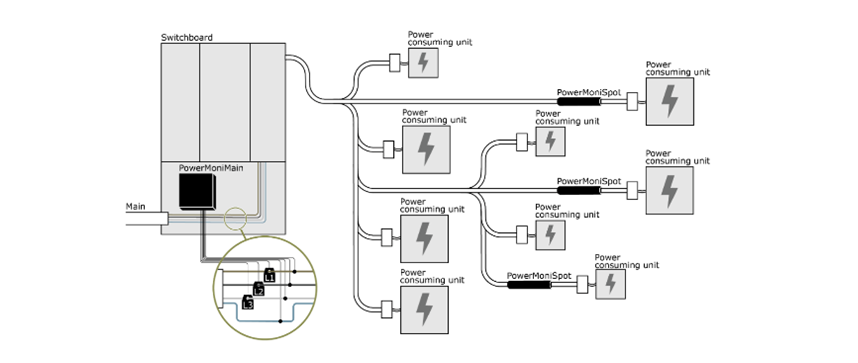

The full solution consists of a central unit (PowerMoniMain) to measure in the central switchboard, and de-central units at each of the critical units needed to be monitored (using PowerMoniSpot).

SnapToPowerQuality full solution scheme

Why SnapToPowerQuality is better than the existing solutions?

- Clamp-on sensors which are easy to click on cables without breaking into the installations. No other known technology can measure from the outside of multiconductor cables.

- Self-learning AI data analysis generates warnings and foresees breakdowns. It sends specific operational messages to the user rather than just collecting data.

- Best Price – Costs for buying, installation and running SnapToPowerQuality are 90% less in comparison to the known alternatives.

- Coherent – the cloud-AI and sensors work as one

- Open data, and easy integration to other systems, through API (Application Programming Interface).

- Highly scalable – it builds on serial produced IoT sensors in combination with cloud operated analytics and integration software.

PowerMoniSpot on multiconductor cable on the left and PowerMoniMain on the right

What is the contribution of ICB?

- Building a common 2-in-1 IoT gateway with ReMoni, which would be able to communicate with ReMoni sensors and industrial equipment or software at the same time.

- Integrating the ICB IoT platform (Upkip) under the hood of ReMoni ReClac platform so that more advanced and complete software solution is created

- Creating new connectors to software manufacturing LoB systems and extending the current library

- Creating new connectors to ingest data and monitor manufacturing equipment

- Pre-production TRL 7 pilot deployments in 3 manufacturing facilities

- Collect and process user feedback to perform improvement in few iterations

- Disseminate and demonstrate results to both manufacturing industry representatives and technical communities to raise awareness of the platform and build a community that would source in suggestions for further development

What is the expected impact of the SnapToPowerQuality power disturbance technology

- Decreased production loss and company resource expenses

- Increased production efficiency

- Reduced energy loss

- Maximized competitiveness of European production lines

Partners in the Fast Track to Innovation (FTI) project

Netherlands

Bulgaria

Denmark

Categories

- EVENTS (5)

- News (44)

- R&D (3)

- Success stories (21)

- Uncategorized (7)